Metalis is focusing on these 6 strategic clusters

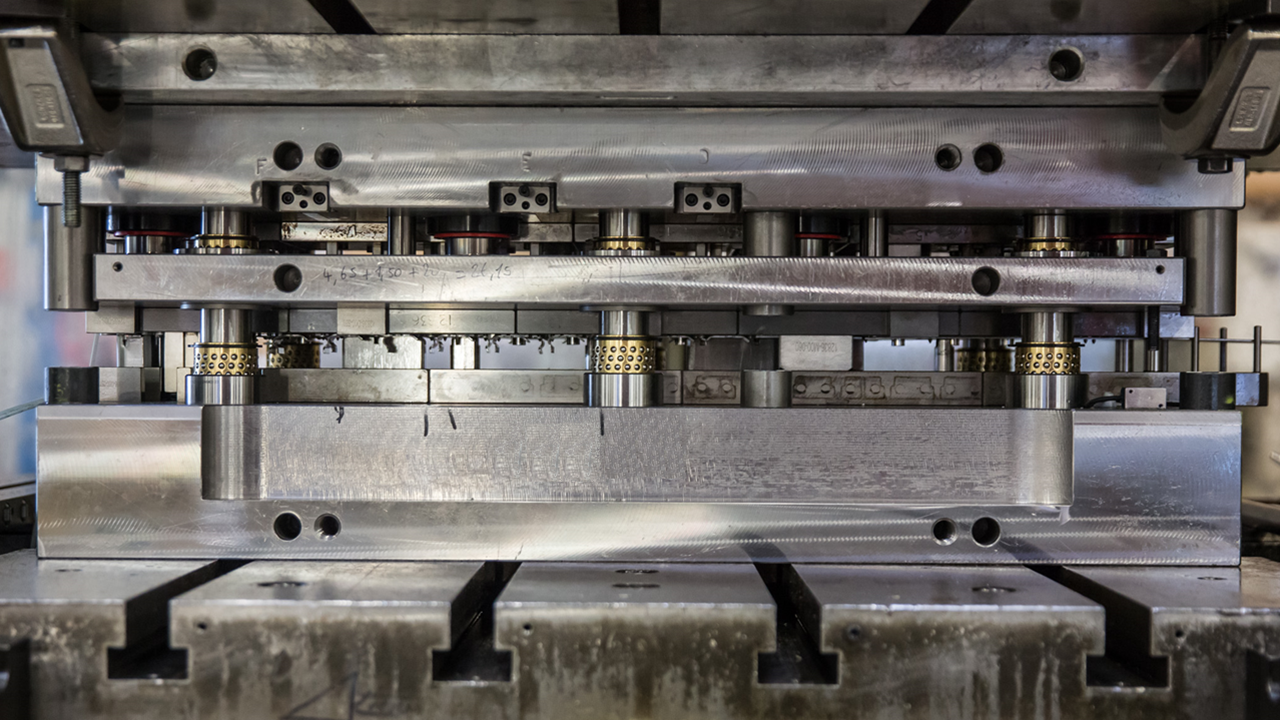

ACCURACY AND PRODUCTIVITY PROVIDED BY THE QUALITY OF OUR TOOLS

This basic technology is pushed at its excellence level, to reach the tightest tolerances (few tenths of microns) and the highest productivity (> 1 million parts per day), for a variety of applications and markets:

- delicate, fragile products: made of copper alloy or stainless steel, these small parts require complex cutting and forming operations, using progressive dies - application / market: electronic lead-frames, MCB terminals for construction industry...

- 9 critical specifications or more: mission critical products with multiple very accurate characteristics to control - application / market: automotive stamped inserts to be overmolded

- shape of cut areas: products requiring cut edges close to machining accuracy, obtained with shaving operations - application / market: rolling surface of a lock for various industries, sharp areas of a connecting system to ensure gripping or crimping function

- swaging, coining: parts requiring thickness deformation to create specific functions (locating, insertion, stopping, deburring...) - application / market: electrotechnical devices terminals for construction industry