new projects prototypes

per year

180 +

new projects industrialized

per year

140 +

R&D headcount

120

toolmakers headcount

60

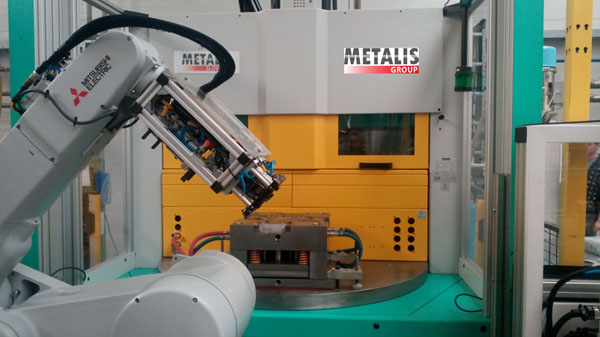

robots / cobots

/ automated processes

150 +

average industrialization

lead-time (weeks)

16

CLICK TO VISIT OUR TECHNICAL CENTRE IN AUGMENTED REALITY

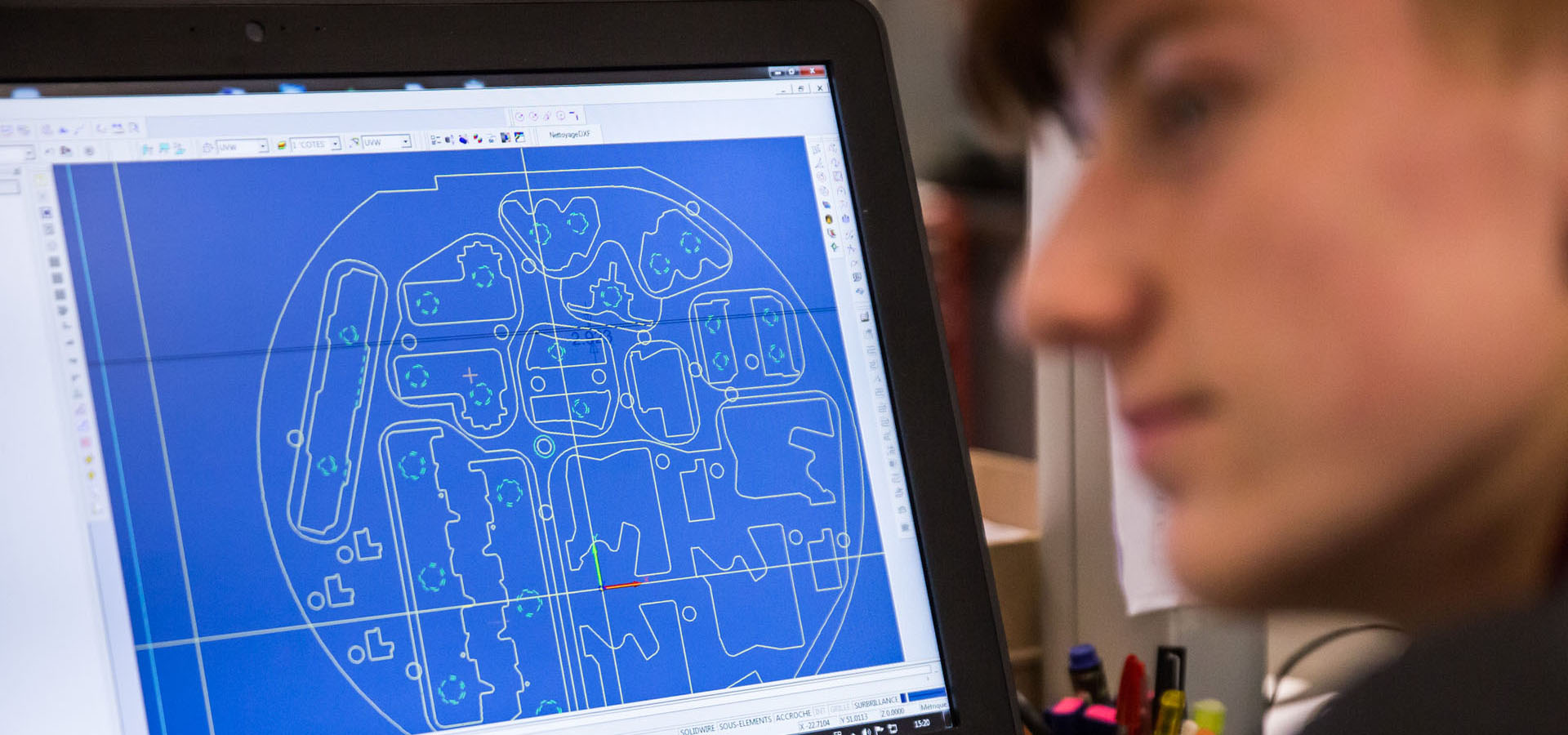

PRODUCT CO-ENGINEERING

- software for 3D products design

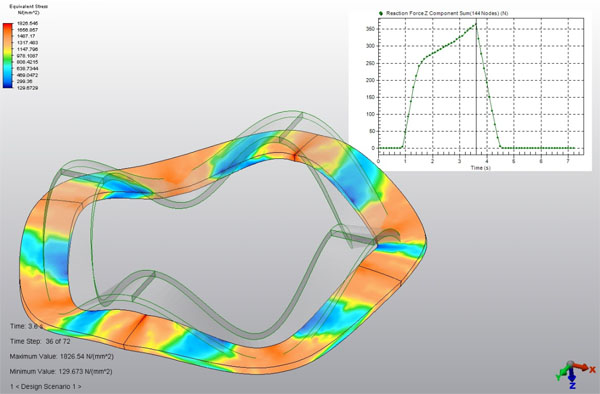

- software for finite elements analysis

- linear and non-linear mechanical, thermal, plasticity simulations

- rheological analysis

- soft tools or 3D printing prototyping

PROCESS ENGINEERING

- in-house expert capabilities

- APQP projects management

- high precision / high speed stamping, deep drawing, multi-slides technologies

- metalloplastic overmolding (reel-to-reel or insert molding)

- assembly in the tool or fully automated lines

- integration of complex processes (tapping, potting, welding, grinding)

- 100% camera and acoustic in-line checking

- particles cleanliness control

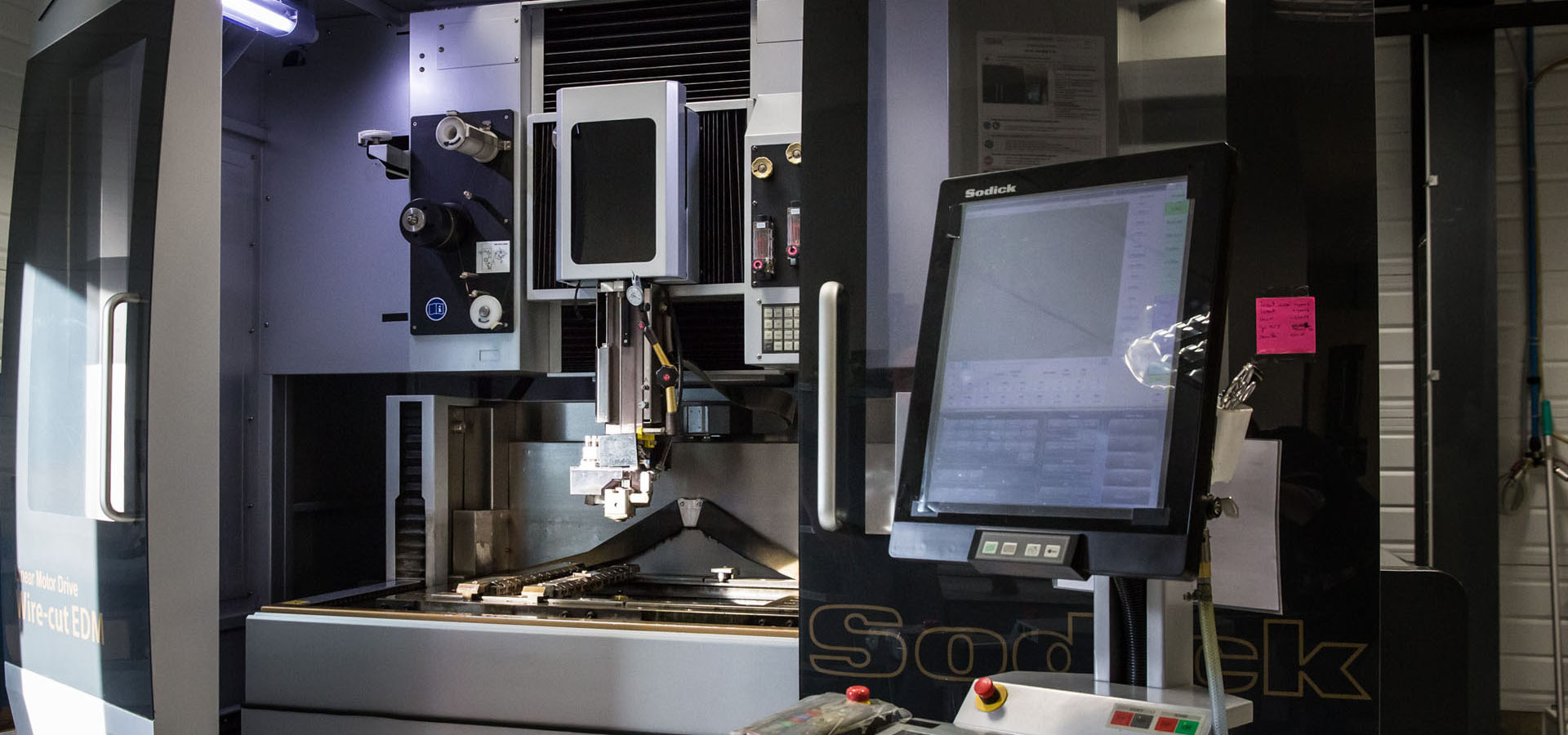

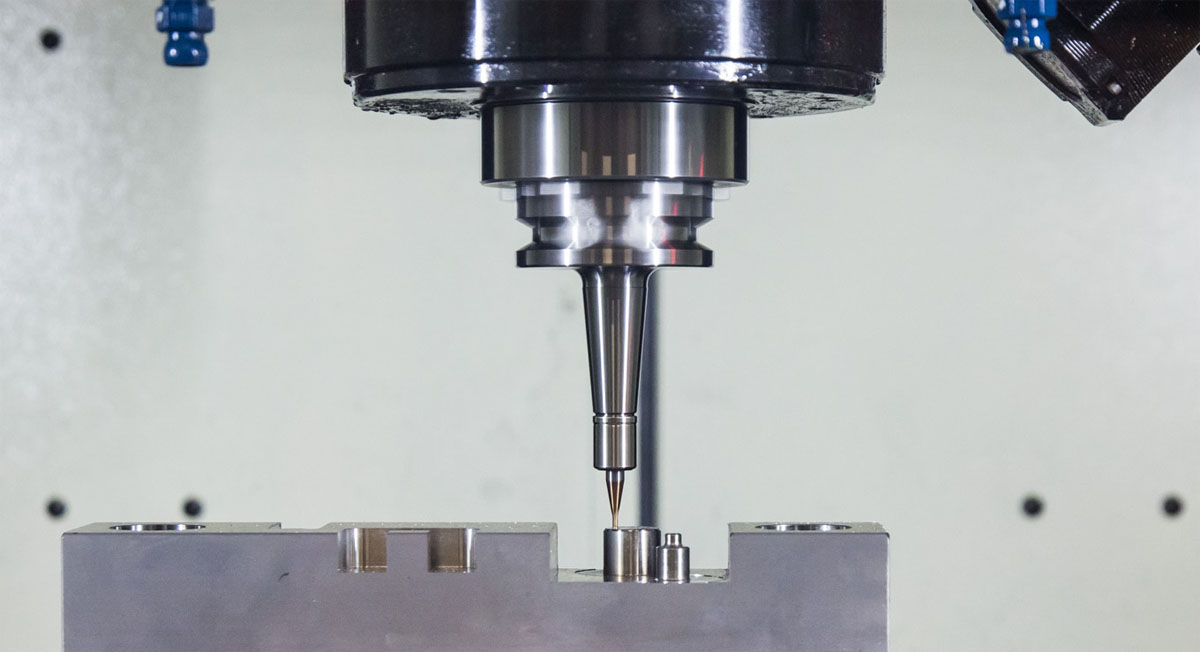

TECHNICAL CENTERS

- each technical center is autonomous with dedicated standardized equipment

- high-speed 3D machining center

- jig grinding machines

- electrical discharge machines (EDM)

- CNC milling centers

- fully equipped and standardized metrology labs

OUR TECHNOLOGICAL EXPERTISE

- product design-to-cost to advise on raw materials, heat treatment, surface treatment

- 70+ years of experience in high accuracy and quality tooling

- 35+ years of experience in metalloplastic overmolding

- 35+ years of experience in assembly in-the-tool

- group senior experts in all technologies